Giới thiệu

Máy cắt laser đã trở thành một công cụ không thể thiếu trong các ngành công nghiệp khác nhau, từ sản xuất và ô tô đến thời trang và trang sức. Độ chính xác, tốc độ và tính linh hoạt của các máy này khiến chúng trở thành một khoản đầu tư có giá trị cho các doanh nghiệp muốn nâng cao năng lực sản xuất. Tuy nhiên, một trong những vấn đề phổ biến nhất đối với người mua tiềm năng là" Máy cắt laser giá bao nhiêu& “; Câu trả lời cho câu hỏi này không đơn giản vì chi phí của máy cắt laser có thể thay đổi đáng kể tùy thuộc vào một số yếu tố. Trong bài viết này, chúng tôi sẽ khám phá các loại máy cắt laser khác nhau, các yếu tố ảnh hưởng đến chi phí của chúng và cung cấp một phân tích chi tiết về phạm vi giá mà bạn có thể mong đợi.

Các loại máy cắt laser

Trước khi đi sâu vào chi phí, điều quan trọng là phải hiểu các loại máy cắt laser khác nhau có sẵn trên thị trường. Mỗi loại có các tính năng, lợi thế và ứng dụng độc đáo của nó, ảnh hưởng đến giá cả tổng thể.

1. Máy cắt laser CO2

- Mô tả: Máy cắt laser CO2 sử dụng laser khí để cắt qua vật liệu. Chúng rất linh hoạt và có thể cắt một loạt các vật liệu, bao gồm gỗ, acrylic, thủy tinh và một số kim loại nhất định.

- Ứng dụng: Thường được sử dụng trong các ngành công nghiệp như biển báo, bao bì và dệt may.

- Phạm vi giá: 5.000 đến 50.000 USD tùy thuộc vào sức mạnh và kích thước của máy.

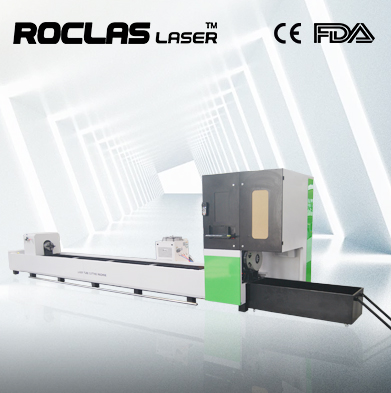

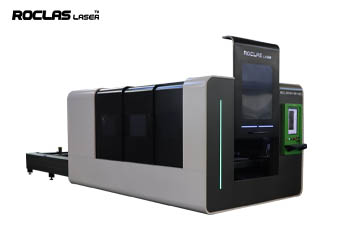

2. Máy cắt laser sợi quang

- Mô tả: Máy cắt laser sợi quang sử dụng nguồn laser trạng thái rắn, hiệu quả và mạnh mẽ hơn laser carbon dioxide. Chúng chủ yếu được sử dụng để cắt kim loại, bao gồm thép không gỉ, nhôm và đồng thau.

- Applications: Widely used in the automotive, aerospace, and metal fabrication industries.

- Price Range: $20,000 to $200,000, depending on the power and size of the machine.

3. Nd:YAG Laser Cutting Machines

- Description: Nd:YAG (Neodymium-doped Yttrium Aluminum Garnet) laser cutting machines are similar to fiber lasers but use a different type of solid-state laser. They are capable of cutting thicker metals and are often used in high-precision applications.

- Applications: Commonly used in the medical, aerospace, and defense industries.

- Price Range: $30,000 to $300,000, depending on the power and size of the machine.

4. Diode Laser Cutting Machines

- Description: Diode laser cutting machines are compact and energy-efficient, making them suitable for small-scale applications. They are less powerful than CO2 and fiber lasers but are ideal for cutting thin materials.

- Applications: Often used in hobbyist projects, small businesses, and educational institutions.

- Price Range: $1,000 to $10,000, depending on the power and size of the machine.

Factors Influencing the Cost of Laser Cutting Machines

The cost of a laser cutting machine is influenced by several factors, including the type of laser, power output, machine size, brand, and additional features. Let's delve into each of these factors in more detail.

1. Type of Laser

- As discussed earlier, the type of laser used in the machine significantly impacts the cost. CO2 lasers are generally more affordable than fiber and Nd:YAG lasers, which are more powerful and capable of cutting thicker and harder materials.

2. Power Output

- The power output of a laser cutting machine, measured in watts, directly affects its cutting capabilities. Higher power machines can cut through thicker and denser materials more efficiently. However, they also come with a higher price tag. For example, a 1000W fiber laser cutting machine will cost more than a 500W machine.

3. Machine Size

- The size of the laser cutting machine, particularly the cutting bed, also influences the cost. Larger machines with bigger cutting beds can handle larger workpieces, making them more versatile but also more expensive. Smaller machines are more affordable but may have limitations in terms of the size of materials they can cut.

4. Brand and Manufacturer

- The brand and manufacturer of the laser cutting machine can also affect the cost. Established brands with a reputation for quality and reliability often charge a premium for their machines. However, investing in a reputable brand can provide peace of mind and ensure long-term performance and support.

5. Additional Features

- Laser cutting machines come with various additional features that can enhance their functionality and ease of use. These features may include automatic focus adjustment, rotary attachments for cutting cylindrical objects, advanced software for design and control, and safety features such as fume extraction systems. Machines with more advanced features will generally cost more.

6. After-Sales Support and Warranty

- The level of after-sales support and the warranty offered by the manufacturer can also impact the cost. Machines that come with comprehensive support, training, and a longer warranty period may be more expensive but can save you money in the long run by reducing downtime and maintenance costs.

Price Range of Laser Cutting Machines

Given the factors mentioned above, the price range of laser cutting machines can vary widely. Here's a more detailed breakdown of the cost based on the type of machine:

1. Entry-Level Machines

- Price Range: $1,000 to $10,000

- Description: These are typically diode or low-power CO2 laser cutting machines designed for small-scale applications, hobbyists, and educational institutions. They are compact, easy to use, and affordable but have limited cutting capabilities.

2. Mid-Range Machines

- Price Range: $10,000 to $50,000

- Description: Mid-range machines include higher-power CO2 lasers and entry-level fiber laser cutting machines. They are suitable for small to medium-sized businesses and can handle a wider range of materials and thicker workpieces.

3. High-End Machines

- Price Range: $50,000 to $200,000

- Description: High-end machines include powerful fiber and Nd:YAG laser cutting machines designed for industrial applications. They offer high precision, speed, and the ability to cut through thick and hard materials. These machines are typically used in large-scale manufacturing and heavy industries.

4. Custom and Specialized Machines

- Price Range: $200,000 and above

- Description: Custom and specialized laser cutting machines are tailored to specific applications and industries. They may include advanced features, such as multi-axis cutting, robotic integration, and high-speed automation. These machines are often used in aerospace, defense, and high-precision manufacturing.

Additional Costs to Consider

When budgeting for a laser cutting machine, it's essential to consider additional costs that may not be included in the initial purchase price. These costs can include:

1. Installation and Setup

- Depending on the complexity of the machine, you may need to hire professionals for installation and setup. This can include electrical wiring, ventilation systems, and calibration.

2. Training

- Proper training for operators is crucial to ensure the safe and efficient use of the machine. Some manufacturers offer training programs, which may come at an additional cost.

3. Maintenance and Repairs

- Regular maintenance is necessary to keep the machine in optimal condition. This can include replacing consumables such as laser tubes, lenses, and nozzles. Additionally, unexpected repairs may be needed, so it's wise to budget for these expenses.

4. Software and Upgrades

- Advanced software for design and control may come at an additional cost. Additionally, software upgrades and updates may be required to keep the machine up-to-date with the latest technology.

5. Accessories and Attachments

- Depending on your specific needs, you may need to purchase additional accessories and attachments, such as rotary attachments, fume extraction systems, and material handling equipment.

Conclusion

The cost of a laser cutting machine can vary widely based on the type of laser, power output, machine size, brand, and additional features. Entry-level machines are affordable and suitable for small-scale applications, while high-end machines are designed for industrial use and come with a higher price tag. When considering the purchase of a laser cutting machine, it's essential to evaluate your specific needs, budget, and long-term goals. Additionally, factor in the additional costs of installation, training, maintenance, and accessories to ensure a smooth and successful investment. By understanding the various factors that influence the cost, you can make an informed decision and choose the right laser cutting machine for your business.

Cho dù bạn cần tư vấn chung hoặc hỗ trợ cụ thể, chúng tôi sẵn lòng hỗ trợ bạn.