Roclas Fiber Laser Cutting Machine: One-Stop Solution for Precision Metal Fabrication

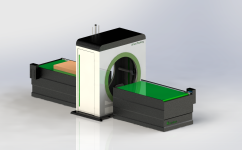

The Roclas Fiber Laser Cutting Machine is a game-changer for metal fabrication businesses looking to streamline operations and boost efficiency. Unlike traditional cutting methods that require separate machines for flat plates and tubes, this innovative solution combines both capabilities into a single unit. Whether you're working with carbon steel sheets or aluminum alloy pipes, the machine delivers consistent precision without the need for constant equipment swaps. Its compact design minimizes factory footprint while eliminating the downtime associated with moving workpieces between stations.

Built with user-friendly integration in mind, the system reduces training overhead and adapts effortlessly to fluctuating order volumes, making it ideal for shops handling diverse, small-batch production runs. By consolidating multiple specialized functions into one system, Roclas helps manufacturers cut costs on labor, energy, and maintenance without compromising output quality.

One of the standout features of the Roclas Fiber Laser Cutting Machine is its ability to handle both flat plates and three-dimensional tubes with exceptional precision. This dual functionality means you no longer need to invest in separate machines for different tasks, saving you significant upfront costs and valuable floor space. The machine eliminates the time-consuming process of transferring and repositioning workpieces between different cutting stations, allowing for a smoother, more efficient workflow.

High-precision cutting is achieved across a variety of shapes and materials, including carbon steel, stainless steel, and aluminum alloys. Whether you're working with round tubes, square tubes, or flat plates, the machine delivers consistent, clean cuts every time. The highly integrated functions simplify operational processes, reducing the need for extensive training and minimizing the risk of human error.

This versatility makes the Roclas machine perfect for businesses that handle diverse, small-batch orders. Instead of juggling multiple dedicated machines, you can rely on a single system to meet all your cutting needs. This not only saves labor and energy but also reduces the complexity of managing different pieces of equipment.

Another major advantage is the non-contact laser processing, which eliminates the wear and tear associated with traditional cutting methods. There's no need to worry about mold degradation or frequent consumable replacements, further lowering your operational costs. With Roclas, you get a reliable, cost-effective solution that adapts to your business needs without the hassle of constant maintenance.

The Roclas Fiber Laser Cutting Machine is more than just a cutting tool—it's a strategic investment for modern metal fabrication. By combining multiple functions into one compact system, it eliminates the inefficiencies of traditional setups, where businesses often juggle separate machines for different tasks. This consolidation not only reduces equipment and maintenance costs but also frees up valuable factory space for other operations. The machine's ability to seamlessly switch between flat plates and tubes without repositioning workpieces translates to faster turnaround times, especially crucial for small-batch orders that require flexibility.

Non-contact laser processing adds another layer of cost savings by eliminating consumables like cutting molds, while its precision ensures minimal material waste. Whether you're working with stainless steel, aluminum, or carbon steel, the machine maintains consistent quality across diverse materials, reducing the need for specialized setups.

For manufacturers aiming to streamline labor and energy use, Roclas offers a practical solution—one machine replaces several, simplifying workflows and cutting overhead. Its intuitive design also shortens training periods, allowing teams to focus on productivity rather than complex operations. In an industry where efficiency directly impacts profitability, this machine stands out as a reliable, adaptable partner for both routine and custom projects.

Get a Quote

Regardless of whether you require general advice or specific support, we are happy to help you.